Sumitomo Rubber Industries says that as a result of joint research undertaken with Professor Yoshitaka Ishii of Tokyo Institute of Technology and Visiting Researcher Muneki Ouchi of RIKEN, it has shed new light “on the mysteries surrounding the vulcanisation process of rubber in tyre manufacturing, which involves chemical reactions between raw rubber and sulphur under intense heat and pressure”.

Focusing on the chemical bonds that form between natural rubber and sulphur as a result of these reactions, it adds, “Our research team has succeeded for the first time in detecting the presence of ring structures, which potentially have an impact on the basic performance of tyres. Moving forward, we will be working to develop new techniques that will allow us to adeptly control the bridge structures and ring structures that fill in and connect the gaps between natural rubber molecules so that we may then utilise this technology to further improve overall tyre performance.”

In 1888, John Boyd Dunlop created the world’s first practical pneumatic tyre. However, this feat would not have been possible without the discovery of vulcanisation in 1839, which set the stage for the development of rubber tyres.

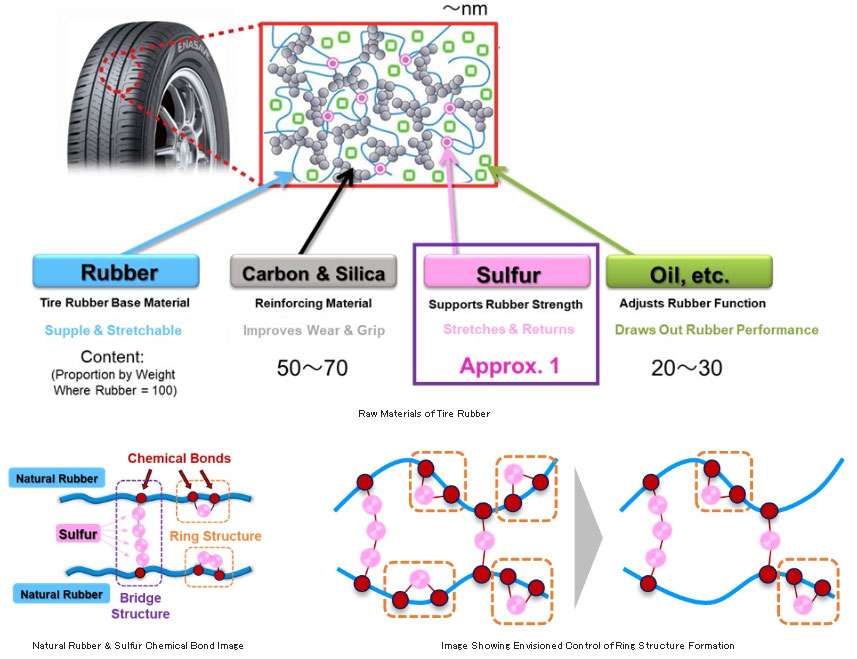

Formed during the vulcanisation process, sulphur bridge structures give rubber its elasticity while playing a major role in basic tyre performance as well as performance retention. However, as sulphur only accounts for around 1% of the raw materials that constitute tyre rubber, prior research has made little progress when it comes to shedding light on the structures of the chemical bonds between rubber and sulphur.

And so, it adds, “Our team set out to advance research in this area with a particular focus on sulphur, a critical raw material that has an outsized impact on tyre performance in spite of making up only 1% of tyre rubber.”

Through this recent research, it says it has not only shed new light on the structures of the chemical bonds that form between natural rubber and sulphur but also succeeded in detecting for the first time the presence of ring structures, which potentially affect the basic performance of tyres.

Furthermore, it intends to apply the results of this research to accelerate the development of “Performance Sustaining Technology,” one of the core technologies of its smart tyre concept for the development of tyres.