South Korea-based tyre maker Hankook plans to boost its business with 3D printing. Together with 3D printing specialist company Tera Works, it recently co-launched a “3D Printing Convergence Technology Centre” at the Hankook Engineering lab in Yuseong-gu, Daejeon.

South Korea-based tyre maker Hankook plans to boost its business with 3D printing. Together with 3D printing specialist company Tera Works, it recently co-launched a “3D Printing Convergence Technology Centre” at the Hankook Engineering lab in Yuseong-gu, Daejeon.

The 3D printing centre spans approximately 661 sq m and is equipped with a wide range of testing apparatus. A team of 15 experts in relevant fields oversees the entire production process, encompassing facility design and manufacturing and post-processing, by utilising 3D printing technology.

In 2015, it became the first company in Korea to introduce a 3D metal printer for the development of mould parts for tyres. Through 3D printing technology, the complex forms of metal printing can be manufactured to reduce processing time, it adds.

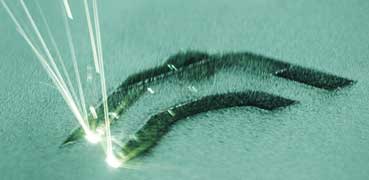

With the goal of expanding its services in the field of precision tyre moulded parts, the centre will develop new kerfs – fine grooves on tyre surfaces – and new tyre moulds.

3D-printed kerf is gaining momentum given its advantages when applied in the manufacturing process of tyres for electric and high-performance vehicles. Noise reduction, improved grip, and enhanced handling are just a few examples of these advantages. As far as technology is concerned, Hankook integrates an in-house metal 3D printer that is used for the manufacture of sipes and other parts for tyre moulds.

The company is now waiting for the results of the 3D printed mould’s feasibility tests for mass production. If successful, it will confirm the process ability to reduce the manufacturing time for tyre sipes and the processing time for mould parts of complex forms.

The announcement follows a collaboration between Hankook’s hardware platform subsidiary Model Solution and Prototech, a domestic 3D printing firm, to escalate rapid prototyping and the 3D printing parts industry.

.