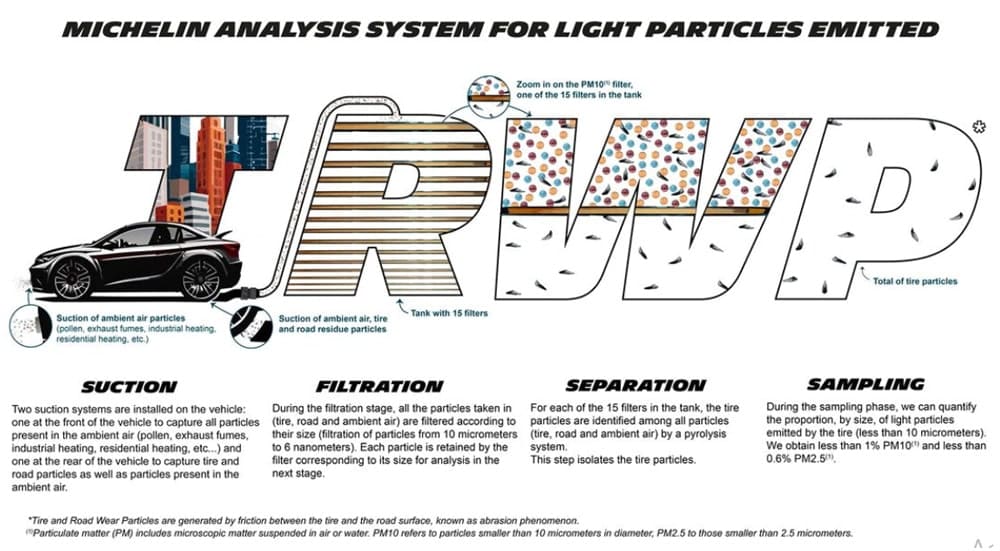

On the road to reduce tyre abrasion and deepen knowledge in this field, French tyre maker Michelin has developed a system for analysing small, emitted particles, known as Sample. This light particle system captures, sorts, counts and characterises particles close up to tyres. This analysis system, presented at recent Tire Technology show, is said to open the way to tyres with wear particles totally bio-assimilable by nature.

There are questions being raised about tyre and road wear particles. This is why it is essential to use reliable, reproducible and standardised measurements and will be a fundamental step in better understanding the environmental impact of these wear particles to innovate and devise new solutions.

Tyre wear particles are on average the size of a human hair (100 µm) and form a complex mixture composed of equal parts of a combination of tyre rubber (50%), minerals and other components of the road (50%).

The Michelin study has quantified the number of these particles that contribute to atmospheric pollution, i.e. PM10 et PM2.5(1) also known as fine particles. Until today, these figures had never been verified by such precise experimental measurements. The initial results show that among the particles emitted by tyres, on average 1.3% are PM10 and 0.16 % of PM2.5 are liable to be found in suspension in the air.

This precise quantification is important both for Michelin to increase understanding of the links between the tire, the road and the driving style and also for the official bodies in charge of estimating city pollution. These data are essential to the design of their simulation models for measuring air quality.

In December 2022 and in March 2023, this study was the subject of two scientific articles https://www.researchgate.net/profile/Frederic-Biesse.

Finally, Michelin has made available this system for analysing emitted light particles to the tyre industry and to ETRMA (European Tyre & Rubber Manufacturers’ Association). The ETRMA will furthermore conduct a campaign of measurements on a larger scale with the aid of an independent third party. It will be launched during 2024 for a duration of around 18 months.

The Euro7 standard that has just been adopted by the European Commission will shortly set down the regulatory tyre abrasion thresholds in order to reduce the quantities of particles emitted in Europe. This regulation has its own test method for quantifying all the wear particles from tyre and the road, in terms of grams per km per ton carried. It enables overall emissions to be measured on a very large scale for all the tyres on the market. Those not meeting the standard will no longer be marketable.

Michelin says it is engaged in a complementary approach, furthering its understanding of this issue.

Since 2005, numerous R&D facilities have been committed to a better understanding and reduction of wear particles emissions. To achieve this, Michelin relies both on its knowledge of materials and on a design strategy historically oriented to optimise the use of materials. This policy secured a 5% reduction in wear emissions of Michelin tyres between 2015 and 2020 which has since continued.

At the end of 2023, the Group announced the creation of a common laboratory with the CNRS and the University of Clermont Auvergne: “BioDLab”. Its mission is to understand the biodegradation of wear particles, for then to develop tools for finding new concrete solutions to make them bio-assimilable by the environment.

The Clermont manufacturer is moreover internationally recognised as a leader in the field of particle emission longevity. A position confirmed by a test carried out by ADAC, the German automobile association (Study published in March 2022) on a hundred or so tyres.

Through these actions, Michelin wants to better understand the phenomenon of tyre wear particles and their degradation process. There are multiple objectives: reduce their emissions, provide scientific responses, and develop concrete technical solutions.