Asahi Kasei has concluded an agreement with Shell Eastern Petroleum Ltd regarding the supply of butadiene derived from plastic waste and biomass. Asahi Kasei plans to begin producing and marketing sustainable solution-polymerised styrene-butadiene rubber (SSBR) using the sustainable butadiene at its plant in Singapore by the end of fiscal 2021 in March 2022.

SSBR is a type of synthetic rubber used mainly for high-performance fuel-efficient tyres (eco-friendly tyres). Demand for eco-friendly tyres is growing worldwide with stricter environmental regulations and heightened environmental awareness. By enhancing fuel-efficiency performance while maintaining safety performance, SSBR is recognised as an optimum material for eco-friendly tyres. To accelerate efforts for decarbonisation to achieve carbon neutrality by 2050, the automotive industry is transitioning to electric vehicles while the tyre industry is further improving the fuel-efficiency and wear resistance of tyres. Against this background, there is rising demand for greater sustainability of SSBR as a material for eco-friendly tyres.

Asahi Kasei says it will be the world’s first company to use butadiene derived from plastic waste, and the first Japanese company to use butadiene derived from biomass, for SSBR production (according to internal research). Throughout the life cycle of tyres from materials, production, use (driving), disposal, and recycling, the proportion of CO2 emissions in the case of internal combustion engine vehicles is highest in the use phase. In the case of electric vehicles, in contrast, use-phase emissions are reduced by a wide margin, making emissions from materials such as SSBR relatively higher. The use of sustainable SSBR therefore enables a significant reduction in CO2 emissions over the life cycle of tyres.

The Japanese company says it continues to focus on technological developments for high-performance SSBR products that enable further improvements to fuel efficiency and wear resistance, in order to meet requirements for increased driving range and mass production of electric vehicles. Additionally, Asahi Kasei has sought to transition to sustainable feedstock in order to reduce CO2 emissions throughout its supply chain.

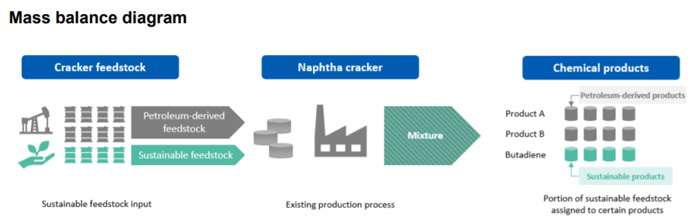

Shell will produce sustainable butadiene by mass balance method* in two ways at Bukom, Singapore. The first is a method of converting plastic waste into pyrolysis oil and feeding it to the naphtha cracker, and the other is using bio-feedstock as a naphtha cracker feed.

* In the case of a mixture of sustainable feedstock and petroleum-derived feedstock in the production process for chemical products, an internationally applied method to assign the portion of sustainable feedstock to certain products.