German auto parts manufacturers, Continental’s pouch conveyor belts are being used in a flood prevention project in Machida, Tokyo.

The city has rivers that are built over or regulated to create space to live. This results in a risk of high waters and flooding. In order to mitigate this risk and protect inhabitants’ living space, the city is building an underground catch basin that can hold up to 150,000 cu m of water. Without it, this volume of water could flood residential areas, shut down public life and threaten the existence of many people.

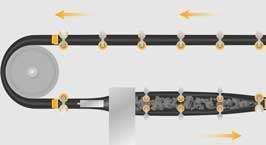

Continental is supplying a special conveyor belt that can be used to transport the material from the excavation of the collecting basin safely, cleanly and quietly from the construction site in the middle of a residential area.

The belt, a low-noise, no-dust, and low-emission transport solution is manufactured in Northeim (Germany) and shipped from there to Japan. The contractors on site are the local Japanese-German joint venture of Continental “Bando-Scholtz” and Furukawa Industrial Machinery Systems, a specialist in Japan in steel construction and industrial equipment, which jointly coordinates and carries out all work for the end customer – the Tokyo Metropolitan.

The pouch conveyor belt meets the requirements of cost-effectiveness and environmental compatibility, according to Masaaki Ogino, CEO of the BandoScholtz. Without the conveyor system, countless trucks would have to drive through the residential area to the construction site over a period of months, resulting in a greater CO2 footprint and more noise pollution, as well as potentially increasing the risk of traffic accidents – particularly in the very restricted infrastructure of the residential area, he said.

The underground catch basin on the Sakai River is intended to protect residents from flooding in the future. Completion is planned for 2024.