Japan’s Zeon Corporation says it has developed and begun operating a new IoT platform to support companywide smart factory initiatives. The platform enables Zeon to visualise and leverage the diverse data generated at its manufacturing sites and R&D centre, helping to improve workplace efficiency and accelerating the adoption of digital technologies.

Since 2020, Zeon has been promoting smart factory initiatives that apply digital technologies to optimise production and improve efficiency while maintaining product quality. At the same time, stable operations remain the company’s top priority. For this reason, systems used in production, including plant control, monitoring, and measurement systems, have been kept independent from other internal networks to block unauthorised external access.

This approach has ensured safety but has also made it difficult to use operational data across the company, posing challenges for the advancement of smart factory initiatives.

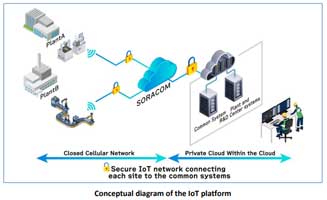

To address this issue and enable the secure companywide use of operational data accumulated at each site, Zeon has established an IoT platform connecting peripheral operational systems. The platform provides a framework that allows on-site ideas to be implemented quickly.

A key feature of the platform is its ability to connect standalone devices such as measuring instruments to the common system and the plant and R&D centre systems in the cloud via a closed network using cellular communication. This design provides a high level of security while also allowing for quick, flexible IoT system deployment. Because cellular connections generally eliminate the need for wired LAN installation, sensors and analysers can be connected easily, enabling site-led installation and rapid deployment.

Zeon adds it has created a communication environment that is internally accessible yet isolated from external networks, simply by installing gateways at locations as required.

The platform was developed with support from Soracom, a provider of IoT platforms, leveraging its communications and cloud technologies as well as specialised consulting.

Ahead of the companywide rollout of the platform, Zeon introduced an equipment monitoring system at the Takaoka Plant, which began full-scale operations in May 2025 following a proof of concept (PoC).

The system has significantly reduced the need for on-site patrol inspections, reducing workloads. In addition, real-time data collection has made it possible to conduct analyses such as early detection of equipment anomalies and predictive monitoring. Several sites are currently conducting PoCs using the platform for IoT projects, and projects that prove effective in the PoC phase are planned for phased rollout to Zeon’s manufacturing sites nationwide.