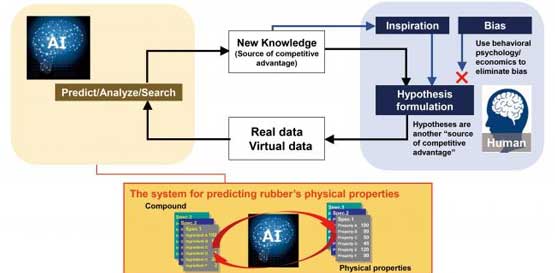

Tokyo-headquartered Yokohama Rubber Co, Ltd is now using the latest AI technology it developed to design rubber compounds for its tyres. The proprietary system, which was developed under Yokohama Rubber’s new AI utilisation concept, HAICoLab (Humans and AI ColLaborate), and launched in October 2020 , can predict the physical properties of rubber compounds. Yokohama Rubber expects the system’s ability to conduct a large number of virtual experiments will enable it to accelerate compound development, reduce development costs, and develop better performing products. The system also will make it easier for less-experienced engineers to create new compounds, according to Yokohama.

The AI system predicts a rubber compound’s physical properties based on the rubber compound design parameters input by an engineer. In addition, to facilitate engineers’ ability to confirm predicted results, the system includes a function that displays the certainty of predicted physical properties and one that searches for a compound composition that will achieve physical properties closest to the targeted ones.

The Japanese tyremaker said that it will expand the use of this new system for developing rubber compounds for use in tyres to a wide range of the company’s other products, including hoses and conveyor belts.

Yokohama Rubber has been advancing technological developments by using AI in its material and tire design and development processes. In 2017, the tyre company also launched a new rubber material development technology that applies materials informatics and a tire design technology that applies informatics technology.In another development, Yokohama Rubber said that its Ibaraki Prefecture-domiciled tyre mould production subsidiary Yokohama Mold Co, Ltd (YMC) will expand production capacity at Yokohama Mold (Thailand) Co, Ltd (YMTC), the Group’s mould production subsidiary in Thailand. Construction of the new facilities began in January 2021, with completion planned for the end of this year.

The expansion at YMTC will supplement the mould supplied from YMC in Japan and a business partner in China, enhancing Yokohama Rubber’s ability to provide a stable supply of tyre mould to its plants in the ASEAN region.