Toyoda Gosei Co., Ltd. and Toyota Central R&D Labs., Inc. have jointly developed new technology that reduces the amount of energy used in the production of rubber products.

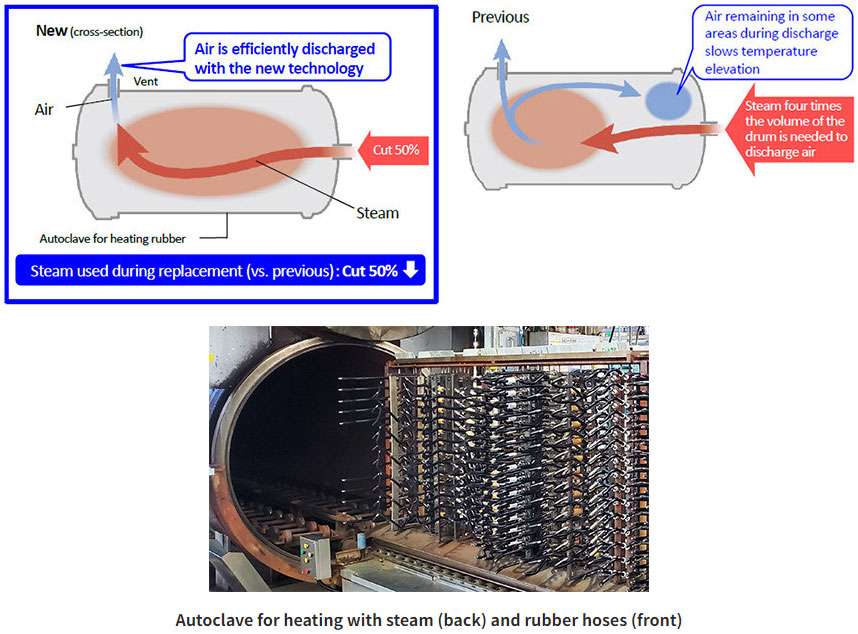

After rubber automotive hoses are formed, they are put in an autoclave and heated with high temperature steam to give them elasticity. During this process, large amounts of steam are used to raise the temperature to a fixed level. Much gas is consumed to create this steam. To reduce the amount of steam used, Toyoda Gosei focused on the process of exchanging the air inside the autoclave with steam and leveraged Toyota Central R&D Labs’ simulation technology that can analyse with high accuracy the airflow and heat distribution within the autoclave.

The new, energy-saving technology, under joint patent pending, reduces by half the amount of steam needed during discharge compared with the previous process.

This technology is currently being used at Toyoda Gosei’s Morimachi plant in Japan and will cut 110 tonnes/year of CO2. The company plans to roll out application of this technology to its other rubber parts plants in Japan and internationally, contributing to the achievement of carbon neutrality by 2050.