Sumitomo Rubber Industries says that it has for the first time adopted the sustainable carbon black for mass-production Dunlop tyres designed for certain passenger car models. The sustainable carbon black is produced via a chemical recycling process* that uses end-of-life tyres (ELTs) and other materials. The production commenced at its Miyazaki Factory in November as part of the company’s efforts to promote recycling of resources.

The sustainable carbon black is manufactured using rubber chippings generated from tire manufacturing processes and crushed ELTs, which undergo a process called chemical recycling. The company says it has been working on it in a joint project with Mitsubishi Chemical Corporation since January 2025.

In August, it supplied racing tyres produced using this material for a real-world racing series: the GT300 Class in Round 4 of the 2025 AUTOBACS SUPER GT, where the vehicle equipped with the tyres took victories two days in a row.

The Japanese firm added that the tyres demonstrated consistently stable performance throughout the race in the motorsports field, which stands at the forefront of tyre development where the latest vehicles are introduced.

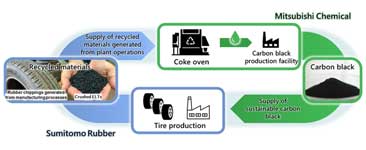

Sumitomo Rubber and Mitsubishi Chemical have formed a collaborative framework where the two companies pursue resource recycling initiatives for carbon black, a primary raw material of tyres. Sumitomo Rubber supplies rubber chippings generated from tyre manufacturing processes and crushed ELTs (recycled materials) to Mitsubishi Chemical.

At Mitsubishi Chemical, these materials are fed into coke ovens for chemical recycling to produce the sustainable carbon black.