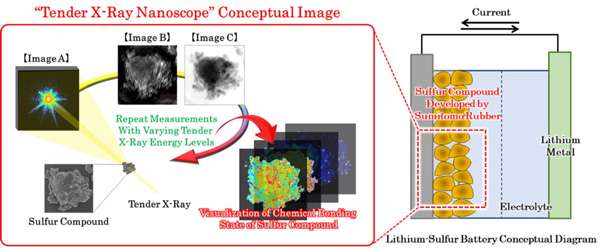

Sumitomo Rubber Industries says that it has established what it says is the world’s first technology that is capable of measuring the structure and chemical state of sulphur compounds at the nanoscale thanks to the active utilisation of the “powerful SPring-8 synchrotron radiation” facility. The technology was achieved as the result of joint research undertaken with Professor Yukio Takahashi of the International Centre for Synchrotron Radiation Innovation Smart at Tohoku University and Riken and Director Yusuke Tamenori of the Japan Synchrotron Radiation Research Institute.

Using this new “Tender X-Ray Nanoscope” technology, it has succeeded in visualising the sulphur compounds used in lithium-sulphur batteries in greater detail than before. It says that practical applications of this technology will bring about new improvements in battery performance by shedding further light on the mechanisms behind lithium-sulphur battery reactions and eventual degradation, which is an area of ongoing R&D. In addition, by applying this technology to future tyre research, it hopes to link the results of this R&D for further improvements to tyres in the future.

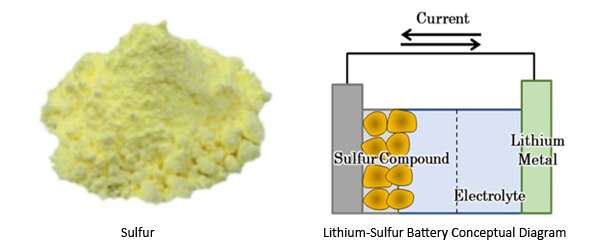

Sumitomo Rubber Industries has long been actively engaged in research involving sulphur, a major raw material in tires that has a significant influence on tyre performance as well as performance longevity. Hoping to apply the knowledge that it had accumulated through tyre research to other fields, it began joint R&D involving lithium-sulphur batteries with the National Institute of Advanced Industrial Science and Technology in 2011.

Lithium-sulphur batteries not only have an expected theoretical capacity that is six to seven times greater than conventional lithium-ion batteries but are also lighter and safer to use. However, the commercialisation of lithium-sulphur batteries has been hindered by their poor cycle life. Improving cycle life will require extremely high-precision measurements of sulphur compounds.

And hence, the development of “the world’s first Tender X-Ray Nanoscope utilising SPring-8”, which enabled the use of “coherent Tender X-Rays”. Thanks to this new measuring technology, it is able to visualise sulphur compounds at the nanoscale.

Moving forward, it is also planning to utilise the 3GeV-class Synchrotron Radiation Facility “NanoTerasu” (which is scheduled to go online in 2024) for measurements of lithium-sulphur batteries under charge-discharge cycling as part of its ongoing efforts to realise practical applications for this technology in the field of materials development.

Sumitomo says it will also apply this technology in its tyre research activities, including deeper analysis of the crosslink structure of the chemical bonds between rubber and sulphur.