The partnership between the world market leader in LSR injection moulding simulation Sigma Engineering and manufacturer of silicone and silicone derivatives Momentive Performance Materials is good news for the silicone processing industry, the companies say. The challenge here is to produce high-precision components with high requirements that simultaneously exhibit thermal expansion and compressibility of all elastomers. The more precise the material data and understanding of the material, the better the predictions made by the simulation. The partnership will offer high added value for this industry thanks to the synergies created, they add.

The partnership between the world market leader in LSR injection moulding simulation Sigma Engineering and manufacturer of silicone and silicone derivatives Momentive Performance Materials is good news for the silicone processing industry, the companies say. The challenge here is to produce high-precision components with high requirements that simultaneously exhibit thermal expansion and compressibility of all elastomers. The more precise the material data and understanding of the material, the better the predictions made by the simulation. The partnership will offer high added value for this industry thanks to the synergies created, they add.

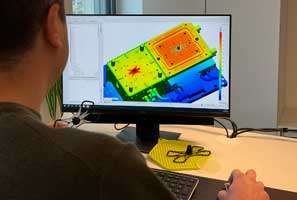

The use of standardised laboratory values for the definition of material laws in the simulation is not sufficient to describe the complex behaviour of components. The observation and consideration of process parameters during processing is not yet part of conventional material data. In future, it will be necessary to use data from real injection moulding processing in order to refine and calibrate the material data. This improves the reliability of the simulation results as well as the material data.

Thomas Klein, Managing Director of Sigma Engineering, is delighted about the partnership and the goals behind it: “Partnerships are formed to create something bigger together and offer added value to the market.”

“We are very much looking forward to working together with Sigma Engineering,” says Holger Albrecht, Vice President and Head of the Elastomer Business Unit at Momentive. “The more precise the material data in LSR processing, the more accurate the simulation can be. This is certainly an advantage for companies in the silicone processing industry – because there is potential for far-reaching optimizations in the manufacturing process.”