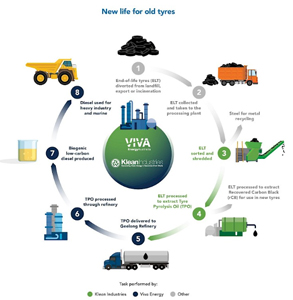

Canada-based Klean Industries and Australian energy infrastructure firm Viva Energy are partnering to launch a tyre recycling initiative at the Geelong Refinery. The initiative aims to transform end-of-life tyres into valuable resources and promote sustainability within Australia’s circular economy. The aim is to develop a tyre recycling facility in Melbourne that would be able to process up to 80,000 tonnes/year of used tyres.

Klean Industries has signed a MOU with Viva Energy Australia to collaborate on a pre-feasibility study to establish a tyre recycling facility to recover sustainable resources.

The facility will extract three key products from end-of-life tyres (ELT):

· Recovered carbon black (rCB): used in the manufacture of new tyres, rubber products, and plastics;

· Steel: for metal recycling; and

· Biogenic pyrolysis oil: that will be processed through Geelong Refinery to produce low-carbon intensity fuels.

Klean uses its technologies to convert waste into valuable resources. It specialises in recovering resources derived from end-of-life tyres, non-recycled plastics, and other waste materials.

Viva Energy Chief Strategy Officer Lachlan Pfeiffer said this project marks a critical step in a new role the Geelong Refinery could play in the future.

“This partnership with Klean Industries is an important development for Viva Energy as we continue to explore new pathways to a more sustainable future for our refinery,” he said. “By transforming end-of-life tyres into valuable resources, we are reducing waste and pioneering new paths for low-carbon fuel production. This project demonstrates our determination to develop a circular economy and deliver environmental and economic benefits for the community.”

Viva Energy is importing to the Geelong Refinery a shipment of tyre pyrolysis oil produced using Klean’s technology. This is an essential step in proving the refinery’s processing of tyre pyrolysis oil at scale and another significant milestone in Viva Energy’s co-processing trials, demonstrating the company’s commitment to creating lower-carbon fuels and products.

If this project proceeds, it will expand the suite of alternative feedstocks utilised at the refinery through co-processing, cementing the facility’s role in Australia’s circular economy and reducing waste going to landfill.

Over the last two months, Viva Energy has announced several projects to utilise alternative feedstocks made from soft plastics, tallow, and used cooking oil at the refinery.