Despite challenges in the global market and supply chain, Asia’s primary rubber producers are successfully achieving their growth targets, with China playing a pivotal role as a major trade partner, adds Angelica Buan in this report.

China: a key figure in the global rubber market

China, the world’s second-largest economy, maintains its leading global position as both the largest producer and consumer of rubber products, primarily owing to its vast manufacturing industry and diverse sectors reliant on rubber. According to Statista, in 2022, China consumed 5.7 million tonnes of natural rubber (NR), meeting demands across automotive, consumer goods, construction, electronics, and manufacturing sectors. China dominates rubber production, including cultivating NR, manufacturing synthetic rubber, and fabricating rubber products.

Presently, China boasts a rubber-planted area spanning 1 million ha across key provinces such as Guangdong, Hainan, Yunnan, Guangxi, and Fujian, renowned as traditional regions for rubber cultivation. Data from the Association of Natural Rubber Producing Countries (ANRPC) suggests China’s potential annual production of NR stands at approximately 1.1 million tonnes.

China’s rapid economic growth, driven by industrialisation and urbanisation, has sharply increased demand for rubber.

Import/exports boosting Asia’s rubber sector

As China’s economy continues its expansion, the corresponding growth in demand for NR, also referred to as ‘white gold’ due to the white liquid or latex extracted from the rubber tree, is evident in the market. Despite being the world’s largest consumer of NR for many years, China’s domestic production capacity falls short, meeting less than half of the domestic demand, thus relying heavily on imports to fulfill its needs.

As China’s economy continues its expansion, the corresponding growth in demand for NR, also referred to as ‘white gold’ due to the white liquid or latex extracted from the rubber tree, is evident in the market. Despite being the world’s largest consumer of NR for many years, China’s domestic production capacity falls short, meeting less than half of the domestic demand, thus relying heavily on imports to fulfill its needs.

Despite fluctuations in manufacturing activity and volatile global prices of rubber and other raw materials, China’s appetite for rubber remains robust. According to the “China’s Natural Rubber Import Industry, 2023-2032” report by China Research & Intelligence, in 2021, China imported nearly 2.39 million tonnes of NR, marking a 3.8% increase year-on-year. The import value surged by 25.4%, reaching US$3.86 billion. Similarly, in the first three quarters of 2022, China’s NR imports continued to rise, reaching almost 1.84 million tonnes, a 10.3% increase year-on-year, with the import value climbing to US$2.99 billion, up by 11.1% compared to the previous year.

China imports four primary types of NR: latex, smoked sheets, technically specified natural rubber (TSNR), and other forms. In February 2024, data from the Observatory of Economic Complexity (OEC) revealed that China’s rubber exports amounted to US$3.42 million, while imports reached US$182 million, resulting in a negative trade balance of US$178 million.

Comparing February 2023 to February 2024, China’s rubber exports surged by 121%, climbing from US$1.55 million to US$3.42 million, whereas imports declined by 36.6%, dropping from US$287 million to US$182 million.

Comparing February 2023 to February 2024, China’s rubber exports surged by 121%, climbing from US$1.55 million to US$3.42 million, whereas imports declined by 36.6%, dropping from US$287 million to US$182 million.

The brisk growth of the automobile and tyre industries is anticipated to drive up demand for NR, which serves as their primary raw material. Despite being a major producer, China is unable to meet its domestic consumption through domestic production alone. Consequently, China heavily depends on imports from neighbouring Asian countries that produce rubber

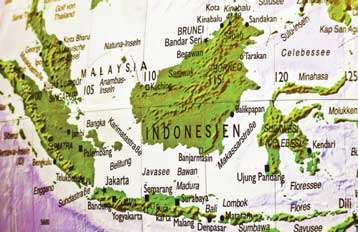

Southeast Asian countries are the main sources of NR imports for China. According to China Research & Intelligence, in 2021, China’s major sources of NR imports by import volume were Thailand, Malaysia, Cote d’Ivoire, Vietnam and Indonesia. Among them, Thailand is China’s largest NR import source. 2021, China imported 1.129 million tonnes of NR from Thailand, accounting for 51.1% of the total NR import volume and US$1.99 billion in import value, accounting for 51.7% of NR import value.