Indian carbon black supplier Birla Carbon is collaborating with NC State University, the National Renewable Energy Laboratory (NREL), Ensyn, The Battery Innovation Center (BIC), and Yale University, to develop and scale-up the production of biocrude-derived graphite for lithium-ion batteries – otherwise known as biocrude-derived anode material (BDAM).

Indian carbon black supplier Birla Carbon is collaborating with NC State University, the National Renewable Energy Laboratory (NREL), Ensyn, The Battery Innovation Center (BIC), and Yale University, to develop and scale-up the production of biocrude-derived graphite for lithium-ion batteries – otherwise known as biocrude-derived anode material (BDAM).

Speaking about this project, Dr. Ann Schoeb, Chief Research and Development Officer, Birla Carbon, said, “The demand for lithium-ion batteries is rapidly increasing and is only expected to accelerate over the next decade. With this project, Birla Carbon aims to establish itself as a key player in the energy systems domain by walking a path of sustainability towards producing these integral materials.”

She further adds, “As a key player in this collaboration project, Birla Carbon will convert the biocrude-derived coke to battery-grade graphite using a new-to-the-world graphitisation technology, which greatly improves the sustainability of battery materials production by both increasing product output and decreasing energy usage.”

Post obtaining the results, the materials characterisation, techno-economic analysis, and life cycle analysis will be conducted at Birla Carbon, NC State, NREL, and Yale.

The company adds that this project aims to produce graphite more sustainably using renewable feedstocks and aligns with Birla Carbon’s goal of sustainability.

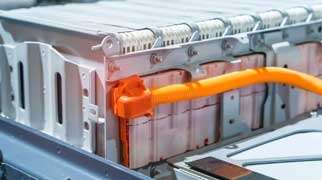

The increase in demand for electric vehicles is primarily fueling the lithium-ion battery market, and portable electronic devices, power tools, residential energy storage, and grid-level storage are applications becoming increasingly dependent on this technology.

Graphite is one of the materials in a lithium-ion battery that stores lithium. Producing battery-grade graphite from biocrude offers a more sustainable pathway toward producing these valuable materials.