Sumitomo Rubber Industries (SRI), in collaboration with Associate Professor Hiroki Ogawa of the Institute for Chemical Research, Kyoto University, has succeeded in three-dimensionally visualising the differences in distribution of rubber’s internal structure that lead to destruction, to allow for the improved development of tyres. This makes it possible to observe in detail the changes in the internal structure of rubber as it is destroyed. Previously, it was not possible to identify where destruction begins when rubber is deformed, or how the internal structure that causes the destruction is related.

This result was achieved through a collaborative project between SRI, which has a wide range of knowledge about rubber materials, and the Institute for Chemical Research, Kyoto University, which has the technology to three-dimensionally visualise the differences in distribution of rubber’s internal structure.

Going forward, the company says it will utilise the results of this research to develop tyres with improved wear resistance, thereby contributing to improved safety and reduced environmental impact.

To date, SRI says it utilised the large-scale synchrotron radiation research facility “SPring-8” to conduct detailed analysis of the internal structure of rubber, in order to develop tyre rubber materials with fuel efficiency and wear resistance .

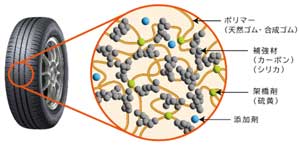

The internal structure of tyre rubber is composed of more than a dozen materials, including the polymer skeleton, reinforcing agents such as silica and carbon black, and additives and crosslinking agents that improve performance.

With conventional methods , X-rays provide average information on the internal structure of the rubber in the area where they pass, so even if the rubber is deformed and destruction occurs, it is not possible to identify where the destruction occurred in the area where the X-rays passed.

Therefore, SRI says it has been working on a collaborative project since May 2023 using a new measurement method developed by Associate Professor Hiroki Ogawa of the Institute for Chemical Research, Kyoto University, to three-dimensionally visualise the differences in the distribution of the internal structure of rubber.

With this method, it has succeeded in capturing where destruction begins when rubber is deformed, and capturing the phenomenon in which the polymer and silica change to a special state (partially aligned state) and the destruction of the rubber begins,

With the spread of EVs leading to an increase in vehicle weight and growing interest in reducing environmental impact through resource conservation, there is a growing need for longer-lasting tyres and the research will aid in this.